2024 is the year of practice.

Practice the principles (discipline = principles + practice)

Practice to be fully engaged in the present moment. Have dedicated time to reflect on the past or to plan for the future. Avoid letting the ego mind hijack and drain my energy.

I chose Kaizen as the fundamental principle for our Organic Learning Organization. In OLO practice, Kaizen can be a philosophy for personal life and a principle for professional work. It is the culture and habit of continuous improvement and change for good.

KAI (改 means change) Zen (善 means good)

Most teachings about Kaizen refer to the word to be Japanese, without realizing that Japanese words have many loanwords from Chinese. According to a Reddit discussion: “49% of Japanese words come from Chinese, and 34% are native. (Another 8% have mixed origin).”

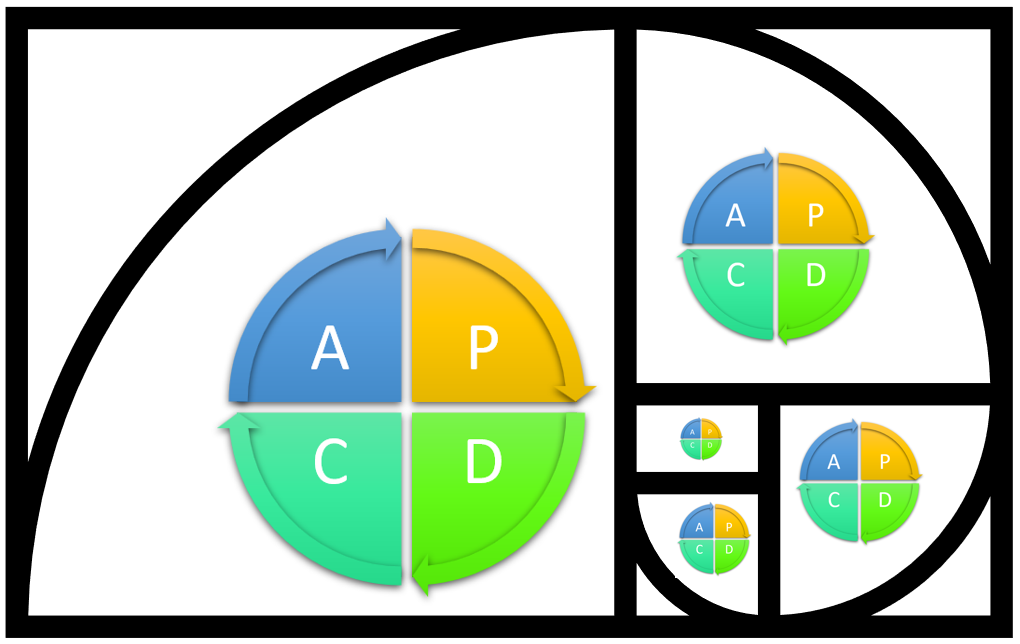

Another important aspect is the fractal nature that OLO understood. Nature uses a simple formula or form and scales up or down with fractals. Check out chaos theory and fractal. You may be fascinated by how elegant nature is, the true master of essentialism. Kaizen practice is fractal. We can practice kaizen over a long cycle of time, or a short duration. We can adopt Kaizen on a personal matter or a grander scale.

Why does Kaizen have to be a small improvement?

“Get 1% better every day.” - Atomic Habits by James Clear

If we reduce the change to the smallest form, it is so tiny that it cannot be ignored (not to do it). A big, ambitious goal without a sustainable execution has a high failure rate.

How do we define the change as ‘tiny’ or ‘small’?

it is so incremental that it does not involve significant redesigning or readjustment, hence consuming little time, effort, and cost.

the activity (change) is so tiny that it is hard to procrastinate and to have excuses not to do it.

small change that is easy to modify, add, remove, edit, measure, test, and do …

no big deal (no significant losses) if the change has no or undesirable impact. We shall ‘do the test’ before ‘act to full roll-out’.

Who should Kaizen?

I prefer Kaizen (Lean) over Six Sigma because Kaizen is not a certification framework like Six Sigma. CEO may not get involved in the Six Sigma process improvement, or the COO may get a Black Belt.

Kaizen can be adopted as a culture and philosophy in the workplace to practice continuous change for positive outcomes. It suits trust & inspires culture, while Six Sigma adopts the traditional command and control approach. Hence, Kaizen is more natural and organic, ideal for organic learning organizations, and could and should be practiced by everyone in the organization.

How to Kaizen?

How do we change for good?

Kaizen was first developed and practiced by Japanese manufacturing after World War II. United States of America sent consultants to help the Japanese industries reform the economy and introduce the Total Quality Management (TQM) practice. The Japanese people refined it to become a cultural practice, a philosophy. Hence, the most common framework for TQM and Kaizen is the Deming Cycle: PDCA, a.k.a Shewhart Cycle.

Like many other users, I am confused by the PDCA's choice of words: Plan—Do—Check—Act. ‘Do’ and ‘Act’ could be easily misinterpreted on the surface level by novice practitioners. The word ‘Check’ may mislead the action to be ensured if the task was carried out, like a ‘checklist’.

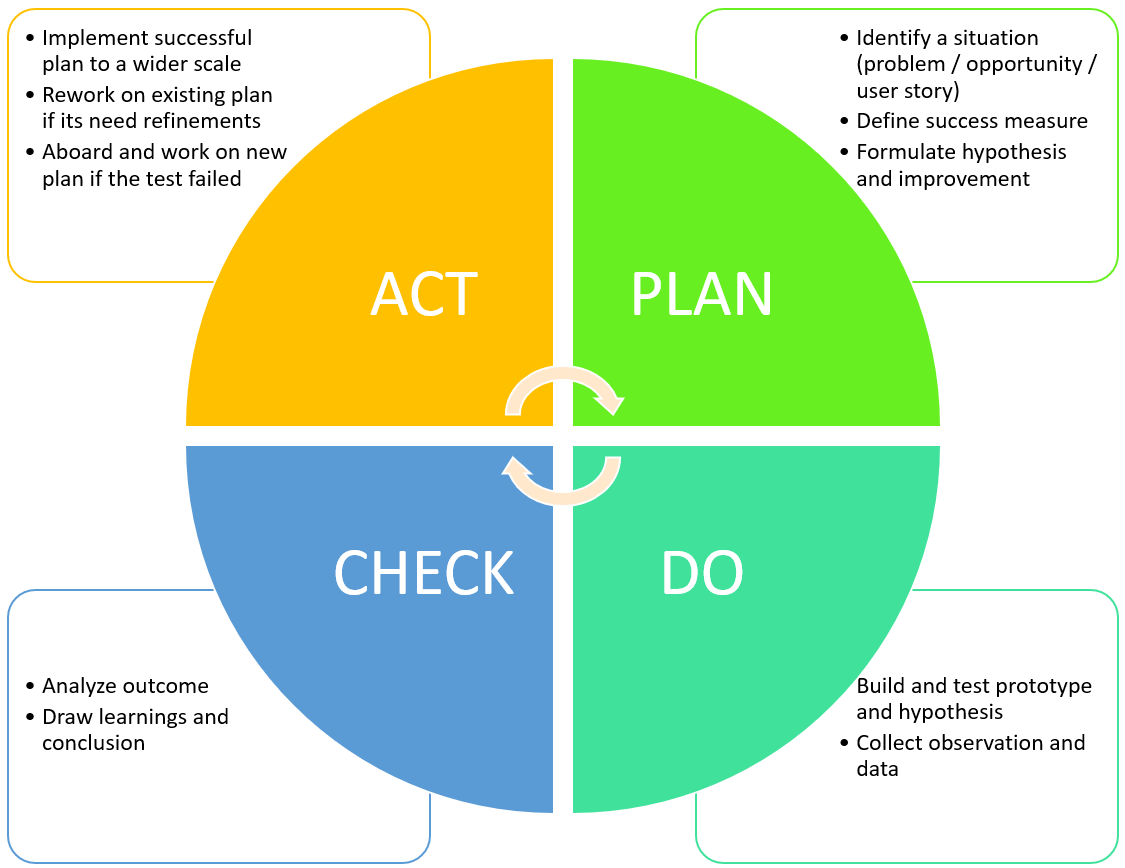

Plan

Identify the user story “Who wants what and why?” or the opportunity/problem we try to improve.

know WHAT problem we are improving.

identify WHO as the stakeholder for the problem we are solving.

WHY is it important to bother? Know the benefits, impacts, or reasons.

Form a hypothesis or an idea that might improve the situation.

What are the success measures? How do we know if the situation has been improved to the target level?

Can we measure the current baseline to compare it with the outcome?

What resources do you need to conduct the experiment?

Do

build prototypes, run experiments, and do pilot tests. Doing it on a small scale in a controlled environment is essential.

Measure baseline, controlled, and experiment data. Collect data and observation.

Check

Verify the outcome of the test if it worked according to the plan (the idea or the hypothesis)

Investigate any outliers or abnormalities.

Draw conclusions and learnings.

Act

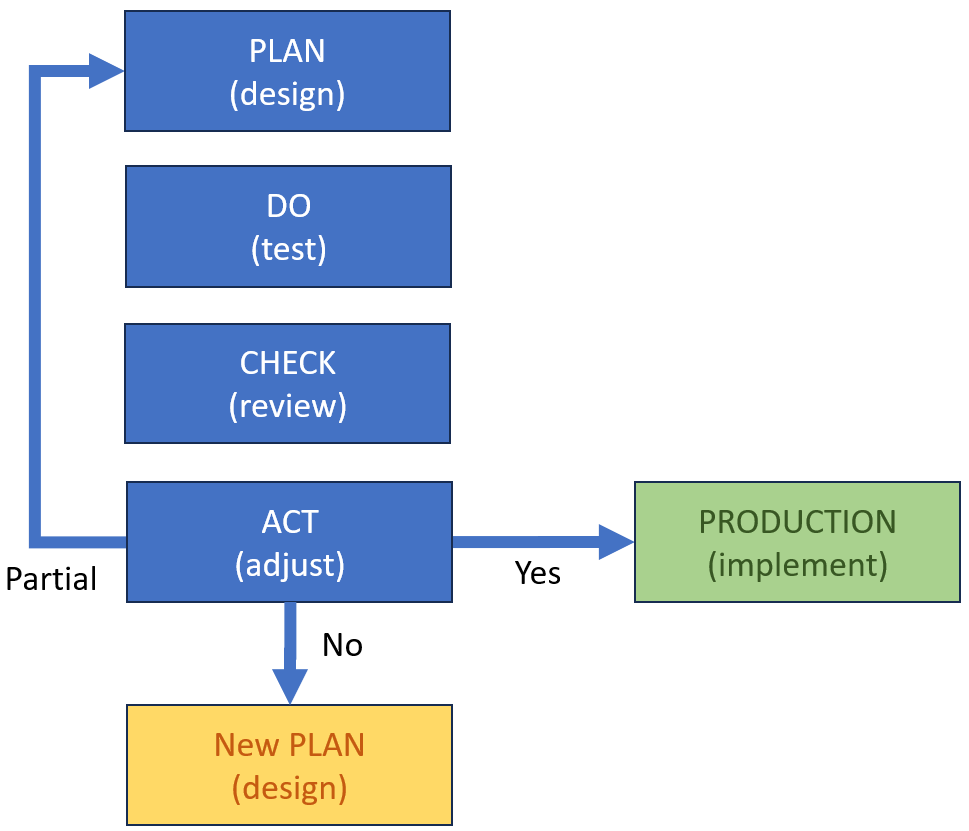

If it did not work as planned, go back to the drawing board, adjust the plan, or aboard the plan.

If it worked partially, see if any refinement is required, refine the plan again, and another PDCA cycle.

If it works as planned, roll it out to the masses and the production.

Hence, many practitioners use the varying term PDSA to improve the abbreviation. This act alone is a Kaizen improvement, too.

Plan - Do - Study - Adjust

I also think of PDCA as PTRA.

Plan - Test - Review - Adjust

Kaizen or its variation is the most quoted improvement in personal development and business improvement teaching. PDCA is so popular that it is mentioned in many frameworks and guidelines. Here are a few examples of the shadow of Kaizen PDCA.

Design Thinking uses the PDCA process flow in the design and development phases.

Atomic Habits: 1% improvement daily. 1% improvement is Kaizen.

Lean: improve quality by eliminating waste. Lean uses PDCA, too.

Six Sigma: DMAIC is similar to PDCA in that it promotes continuous improvement. DMADV involves process re-engineering.

ISO: recommends the use of PDCA for continuous improvement.

Define Success: Achieving or Achievement

The biggest takeaway from Thomas Sterner's book The Practicing Mind is the teaching of the agony we put ourselves into when we define success. We are conditioned to judge by labeling everything good or bad and evaluating everything by grades.

When we study in school, the success of a good student is measured by the academic grade.

When we work in the professional arena, success is measured by fame, power, and wealth.

When we do anything, success is measured by the achievement of the end goal, which is a perfect state. We will be happy when we attain this ideal state.

Due to the gap between now and the future perfect state, we can reduce a lot of energy drainage (waste), guilt, and disappointment (negative emotions) by redefining success as “the daily deliberate practice of continuous improvement to achieving the goal.” Note the subtle yet critical difference of changing from associating ‘achievement’ to ‘achieving’. Refocus on wanting the end goal (achievement) to engage with the process (achieving).

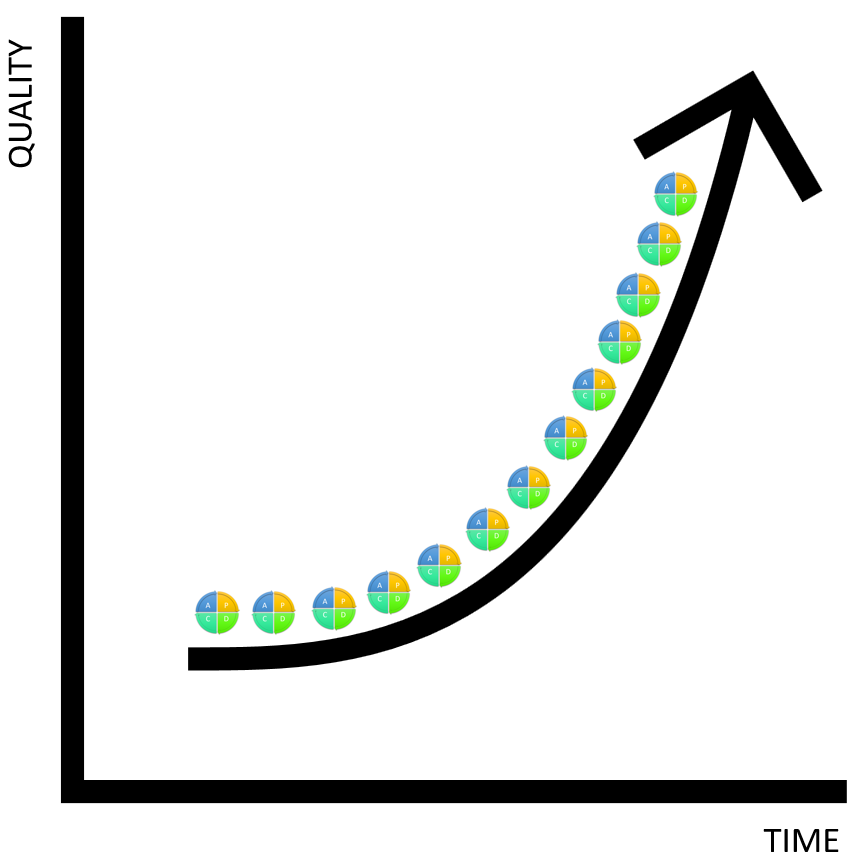

We have a good day if we practice (really execute) some form of PDCA. We have a good week when we practice 7 days, and we have a great year when we practice this for 52 weeks.

If we are studying, we should measure success by the learning attitude and the student's effort into learning. The practice of continuous learning is the success, not how many ‘A’s we scored in the kindergarten.

In short, I learned that:

Kaizen is a fractal in nature.

Kaizen has to be a small improvement and take compound effect to realize its impact.

For continuous improvement to be sustainable, Kaizen has to become a habit and a culture. The discipline of constantly practicing Kaizen as a principle and system is more sustainable than merely setting goals.

Focus our energy on the present moment, immerse ourselves in what we are doing, engage in Kaizen, and associate success with archiving the tiny improvement (avoid the pitfall of defining our success by achieving the end goal).